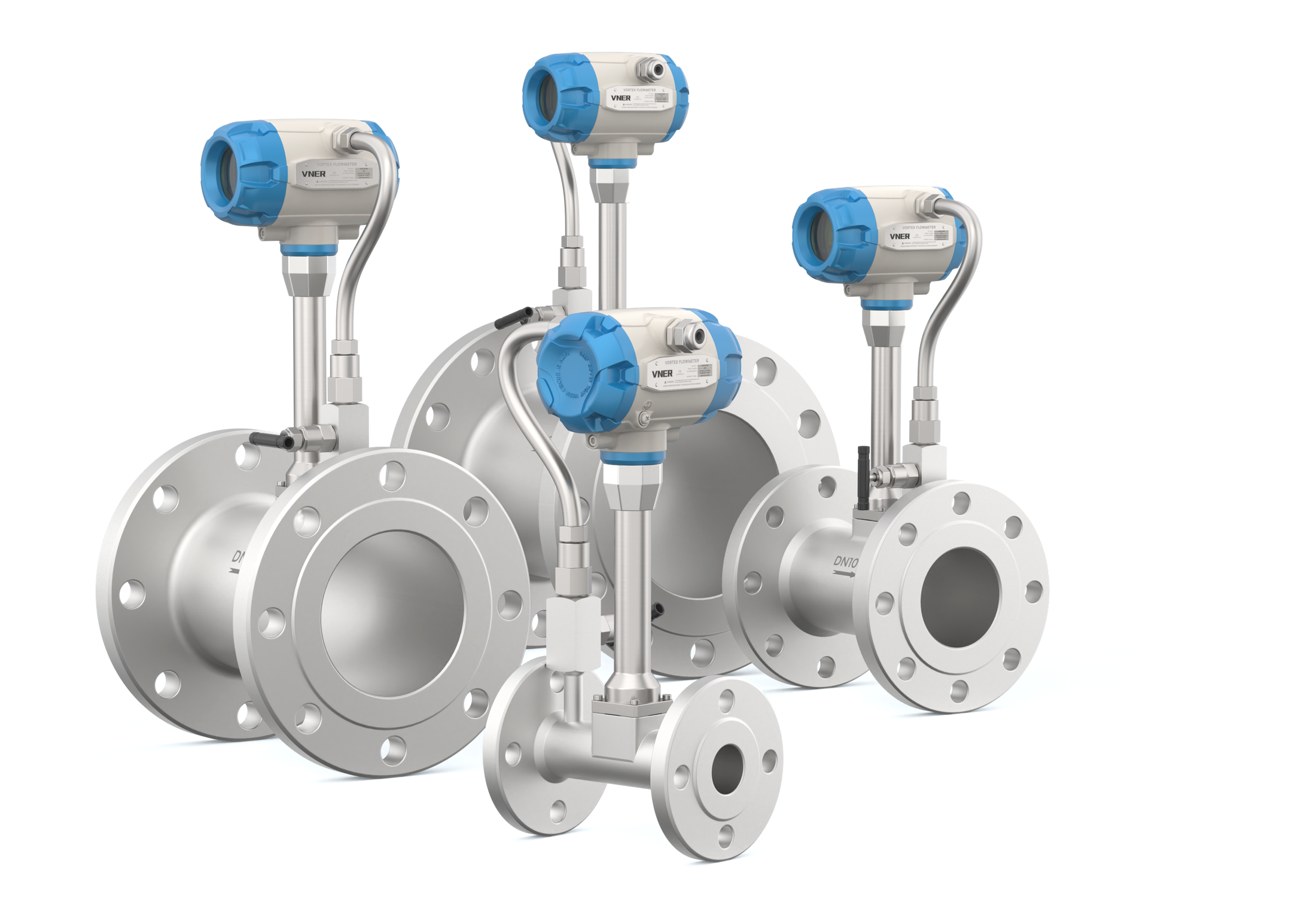

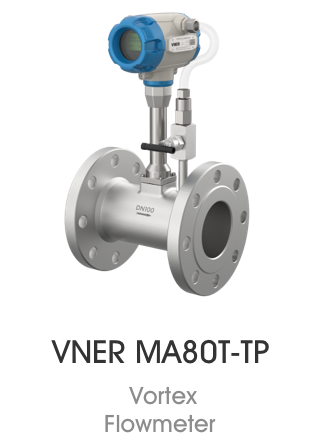

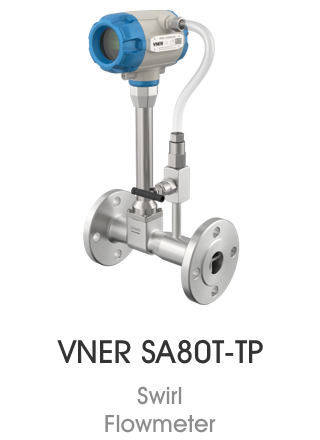

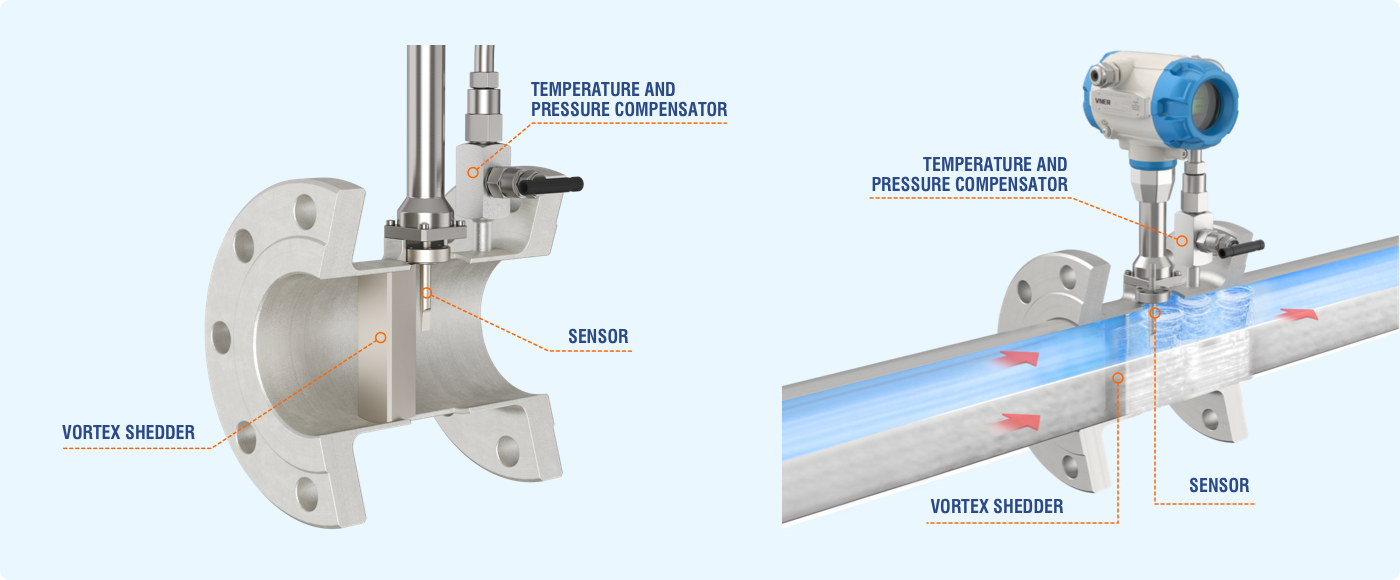

The MA80T-TP series vortex flowmeter strictly follows the principle of reliability in its design, adopting an optimized design scheme with simplified structure. The entire series of product components achieve high universality and interchangeability; The circuit components use new components with high reliability indicators and adopt surface mount technology, eliminating low reliability components such as potentiometers and connectors, significantly improving the overall reliability indicators of the machine.

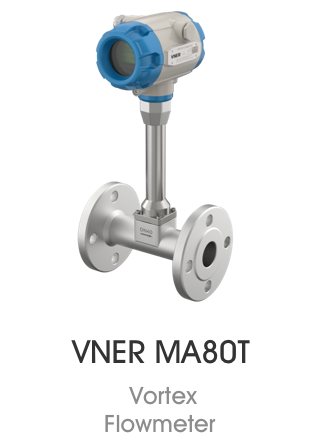

Vortex flowmeters have become the standard for many industrial process applications, particularly for measuring gas and steam flow rates, over the last 30 years.