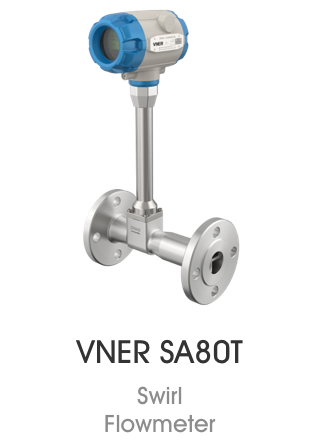

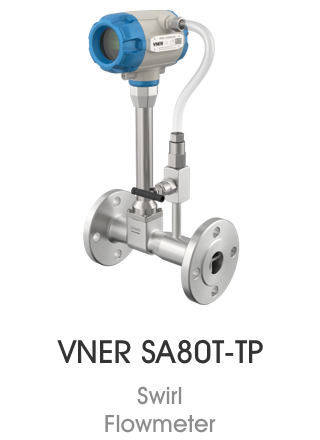

The Swirl flowmeter utilizes the principles of vortex shedding that occur when a fluid flows past a bluff obstacle in its path.

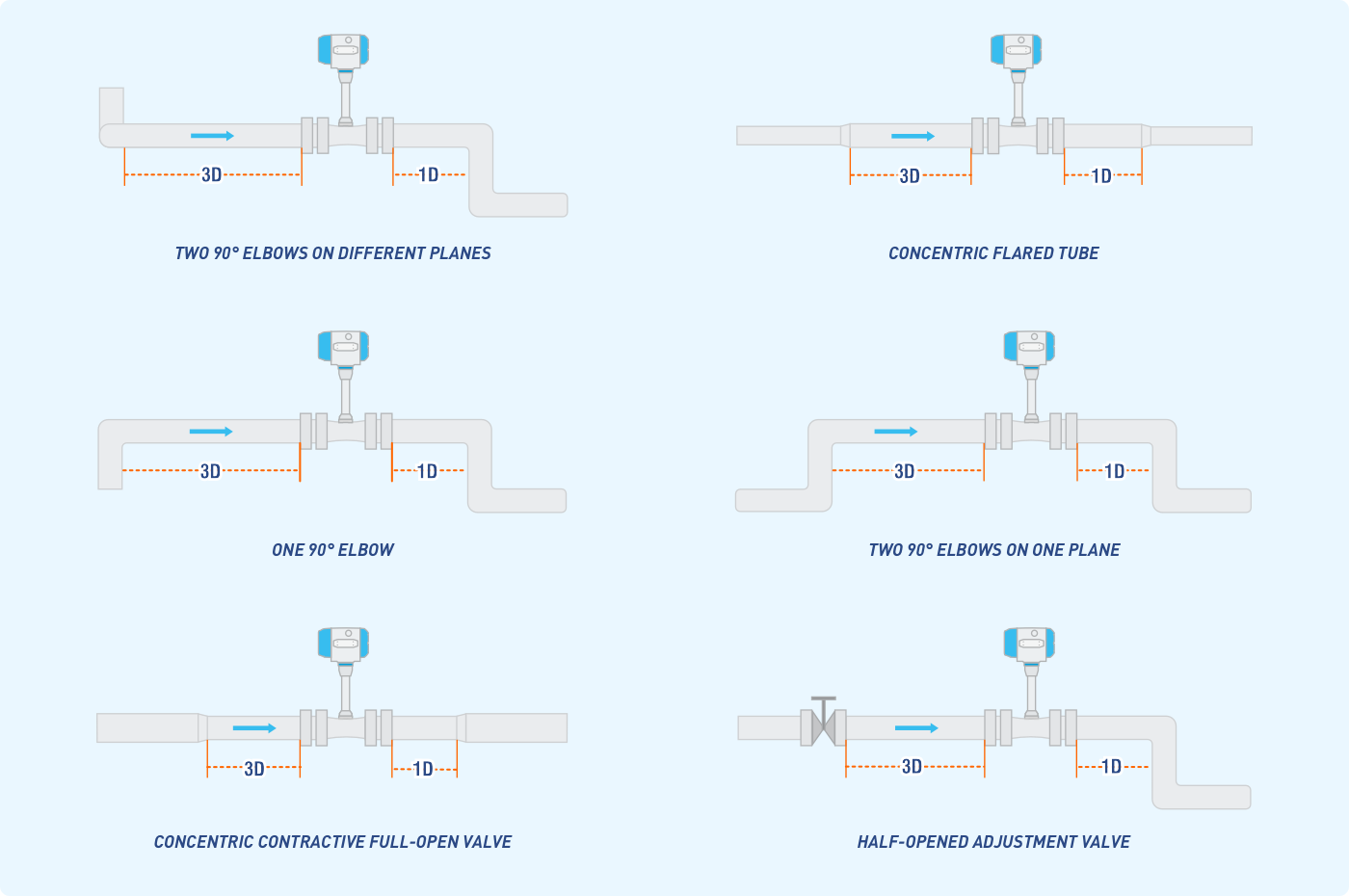

The Swirl flowmeter, however, has an added twist in the way it conditions the fluid, resulting in improved performance while reducing installation considerations.

The Swirl flowmeter is similar to the vortex flowmeter in terms of technology. It utilizes the principles of vortex shedding that occur when a fluid flows past a bluff obstacle in its path. The Swirl flowmeter, however, has an added twist in the way it conditions the fluid, resulting in improved performance while reducing installation considerations.

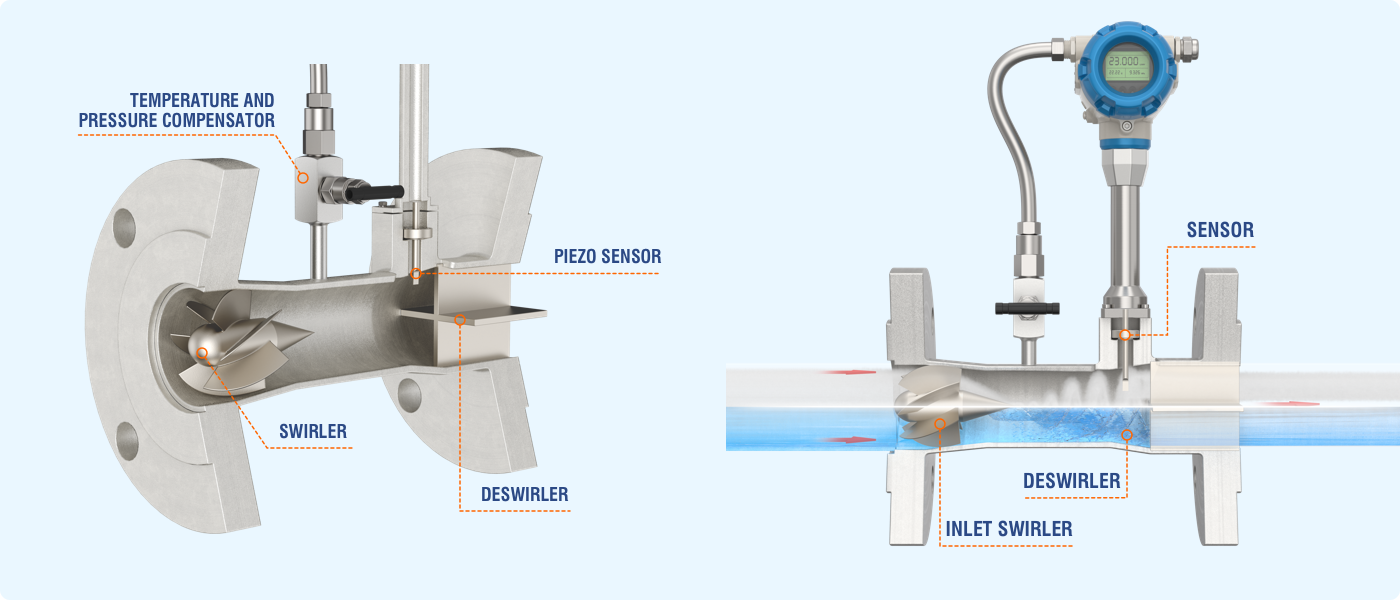

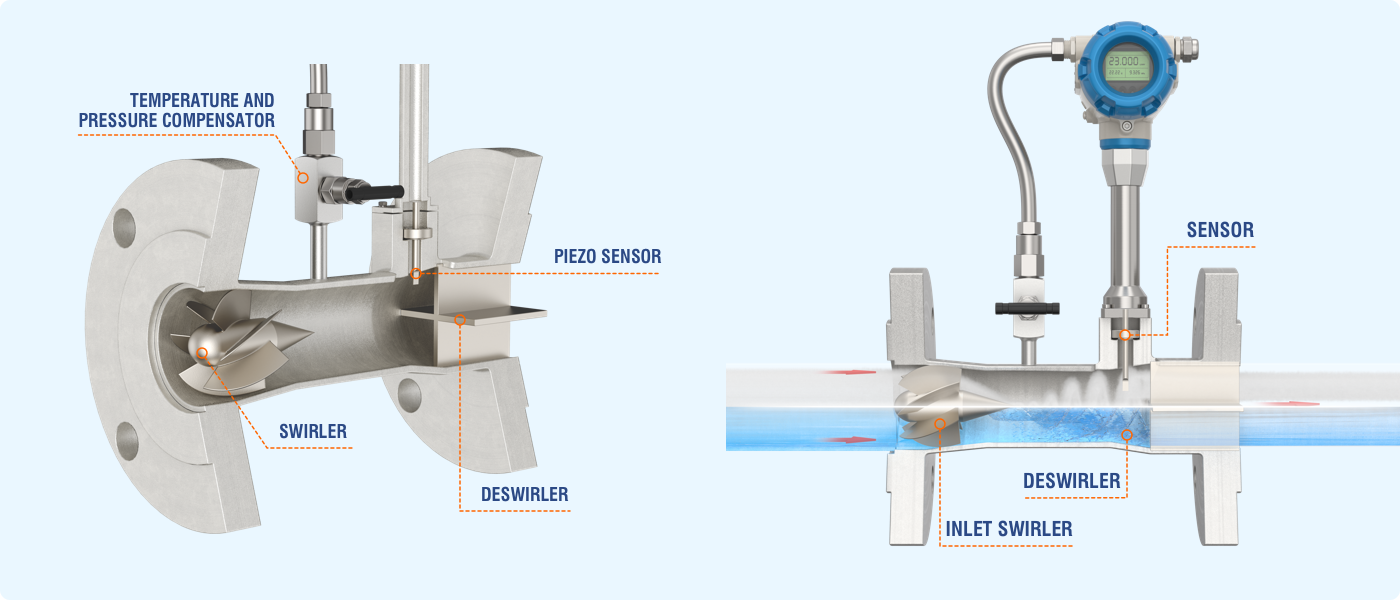

The Swirl flowmeter works by channeling the incoming fluid through a Swirl-inducing element (Swirler) fixed at the upstream inlet of the meter body. The Swirler imparts a tangential velocity to the fluid and then accelerates its flow via a reduction in the meter body bore. The Swirler generates a low-pressure zone at the core of the primary fluid rotation.

As the fluid approaches the meter outlet, the flowmeter's bore increases and decelerates the fluid to its original velocity. The deswirler, welded to the flowmeter body near the outlet, eliminates the tangential velocity imparted to the fluid at the inlet. This avoids any interference with the operation of other downstream instrumentation.